GE IS200DAMAG1BCB Speedtronic Turbine Control PCB board

General info

| Manufacture | GE |

| Item No | IS200DAMAG1BCB |

| Article number | IS200DAMAG1BCB |

| Series | Mark VI |

| Origin | United States(US) |

| Dimension | 180*180*30(mm) |

| Weight | 0.8 kg |

| Customs Tariff Number | 85389091 |

| Type | Speedtronic Turbine Control PCB board |

Detailed data

GE IS200DAMAG1BCB Speedtronic Turbine Control PCB board

The GE IS200DAMAG1BCB is a specific model of a printed circuit board (PCB) used in GE's Speedtronic turbine control systems. These systems are part of the Speedtronic control architecture, which is a family of control systems designed for gas and steam turbine operation. The IS200DAMAG1BCB board is used for a variety of functions in these systems, including processing inputs and controlling turbine parameters.

This PCB is used in turbine control systems, which are involved in supervising the operation of gas and steam turbines. It typically processes analog and digital signals related to turbine control and protection.

Signal processing for turbine monitoring and control. Interfaces with other components in the Speedtronic system for protection and control functions. Handles diagnostics and fault detection to ensure the turbine is operating within safe parameters. Communications between different subsystems in a turbine control setup.

The IS200DAMAG1BCB typically has various chips, resistors, capacitors, and other passive/active components that are essential for turbine control functions. Connectors and communication ports for interfacing with the turbine control system, enabling it to receive and transmit signals.

The Speedtronic Turbine Control System is a complex system that monitors and controls the performance of industrial turbines. It includes functions such as regulating turbine speed, temperature, vibration, and other critical factors to ensure efficient and safe operation. The IS200DAMAG1BCB is part of this system and works in conjunction with other boards and modules to maintain turbine performance.

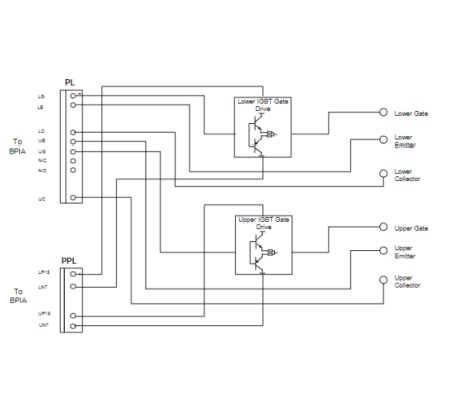

The DAMA, DAMB, and DAMC boards amplify current to provide the final stage of gate drive for the phase legs of the driver power bridge. They accept a +15/-7.5 supply input. The DAMD and DAME boards provide an unamplified interface with no supply input.

The InnovationSeries™ 200DAM_ Gate Drive Amplifier and Interface Boards (DAM_) provide the interface between the control frame and the power switching devices (insulated gate bipolar transistors) of the InnovationSeries low voltage drivers. They include LEDs to indicate the on and off states of the IGBTs

The gate drive boards are available in six variants, determined by the drive power rating

DAMA 620 frame

DAMB 375 frame

DAMC 250 frame

DAMD Glfor=180 frame: G2 for 125 or 92 G2 frame

Frequently asked questions about the product are as follows:

-What is the GE IS200DAMAG1BCB Speedtronic Turbine Control PCB Board?

The IS200DAMAG1BCB is a printed circuit board (PCB) used in GE's Speedtronic turbine control systems. These systems are designed to control and protect gas and steam turbines. The IS200DAMAG1BCB board is involved in processing turbine signals, managing control parameters, and ensuring safe operation.

-What components are on the IS200DAMAG1BCB PCB?

The IS200DAMAG1BCB board contains various components, connectors for communication with other modules in the Speedtronic system. LEDs or indicators for indicating operating status and errors.

-How do I replace the IS200DAMAG1BCB PCB?

1. Always shut down the turbine control system before removing or replacing components to prevent electrical damage or personal injury.

2. Carefully disconnect any wiring or communication cables connected to the board. Unscrew or loosen the board from its mounting.

3. Place the new IS200DAMAG1BCB circuit board into the mount and securely connect all cables and wires.

4. Turn the system back on and check for normal operation, ensuring there are no error codes or system alarms.