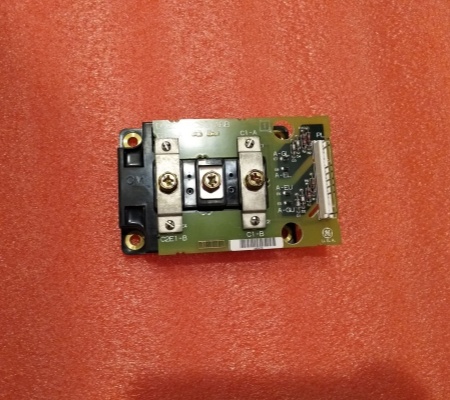

GE DS200IPCDG1ABA IGBT P3 DB SNUBBER C

General info

| Manufacture | GE |

| Item No | DS200IPCDG1ABA |

| Article number | DS200IPCDG1ABA |

| Series | Mark V |

| Origin | United States(US) |

| Dimension | 160*160*120(mm) |

| Weight | 0.8 kg |

| Customs Tariff Number | 85389091 |

| Type | IGBT P3 DB SNUBBER C |

Detailed data

GE DS200IPCDG1ABA IGBT P3 DB SNUBBER C

Product Features:

Designed specifically for GE gas and steam turbines, the SPEEDTRONIC™ Mark V gas turbine control system uses a large selection of CMOS and VLSI chips to minimize power consumption and maximize functionality. The new design consumes less power than previous generations of equivalent panels. Ambient air at the panel inlet vent should be between 32 F and 72 F (0 C and 40 C) and humidity should be between 5% and 95% non-condensing. The standard panel is a NEMA 1A panel, 90 inches high, 54 inches wide, 20 inches deep, and weighs approximately 1,200 pounds. Figure 11 shows the panel with the door closed.

For gas turbines, the standard panel operates on 125 volt DC unit battery power, with an AC auxiliary input of 120 volts, 50/60 Hz for the ignition transformer and processor. A typical standard panel will require 900 watts DC and 300 watts auxiliary AC. Alternatively, auxiliary power can be 240 VAC 50 Hz or supplied by an optional black start inverter from the battery.

The power distribution module conditions the power and distributes it to the individual power supplies for the redundant processors via replaceable fuses. Each control module is powered by its own regulated DC bus via an AC/DC converter. These converters can accept a very wide range of input DC, which allows the controller to withstand significant battery voltage drops, such as those caused when starting a diesel engine. All power supplies and regulated buses are monitored. Individual power supplies can be replaced while the turbine is running.

Frequently asked questions about the product are as follows:

What functions does the GE DS200IPCDG1ABA have?

The module has a built-in self-diagnosis function that can monitor its own working status in real time. It will check whether its own circuit is normal, whether there are hidden faults in electronic components, and whether there are abnormalities in the signal processing process.

Monitor system-level faults. It will determine whether the entire industrial control system has faults by analyzing the various signals received and the communication with other modules.

In what fields can GE DS200IPCDG1ABA be used?

In the control systems of various power generation facilities such as thermal power generation, hydropower generation, and wind power generation, DS200IPCDG1ABA can be used to collect and transmit equipment operation data.

In various industrial automation production lines, such as automobile manufacturing production lines, electronic equipment manufacturing production lines, etc., this module can be used to process sensor signals from various links of the production line to monitor and control the production process and improve production efficiency and product quality.