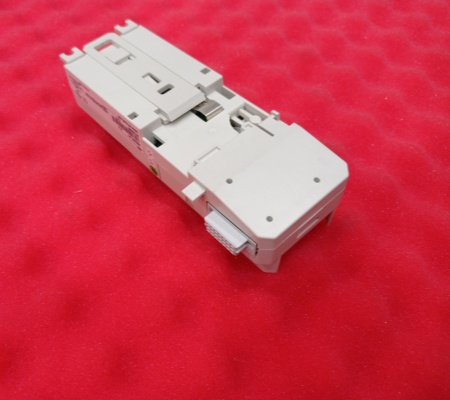

ABB TU814V1 3BSE013233R1 Compact MTU 50V Snap In Con Module Termination Unit

General info

| Manufacture | ABB |

| Item No | TU814V1 |

| Article number | 3BSE013233R1 |

| Series | 800xA Control Systems |

| Origin | Sweden |

| Dimension | 73*233*212(mm) |

| Weight | 0.5kg |

| Customs Tariff Number | 85389091 |

| Type |

Compact Module Termination

|

Detailed data

ABB TU814V1 3BSE013233R1 Compact MTU 50V Snap In Con Module Termination Unit

The TU814V1 MTU can have up to 16 I/O channels and two process voltage connections. The maximum rated voltage is 50 V and maximum rated current is 2 A per channel.

The TU814V1 has three rows of crimp snap-in connectors for field signals and process power connections. The MTU is a passive unit used for connection of the field wiring to the I/O modules. It also contains a part of the ModuleBus.

Two mechanical keys are used to configure the MTU for different types of I/O modules. This is only a mechanical configuration and it does not affect the functionality of the MTU or the I/O module. Each key has six positions, which gives a total number of 36 different configurations.

TU814V1 provides a secure interface for connecting field devices to ABB control systems. It supports various types of digital I/O, analog I/O and application-specific connections. Snap-in terminals ensure that wiring is fast, organized and secure, reducing the possibility of installation errors.

Frequently asked questions about the product are as follows:

-What is unique about the ABB TU814V1 in terms of installation?

The TU814V1 features snap-in connection technology, which allows for quick installation of field wiring without tools. This feature reduces installation time and ensures safe and reliable connections.

-Can the ABB TU814V1 handle signals other than 50V?

Although the TU814V1 is designed for 50V signals, it is well suited for digital and analog I/O devices that operate at 50V. For devices that require higher or lower voltages, ABB's other terminal units may be more appropriate.

-How does snap-in technology improve the installation process?

Snap-in technology eliminates the need for tools during the installation process. Simply snapping the wires into the terminal block speeds up the installation process and reduces the possibility of errors. This is particularly useful in applications that require a large number of field connections.